|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Using Dupont Imron Polyurethane as lettering enamel

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Apparently, Dupont makes at least two kinds of Imron. The one I used for this experiment was their industrial type. Tom at

Premier Automotive Color LLC, 2725 N Wright Rd, Alcoa, TN. Tel: 865-970-9273

said that this was slower drying than other formulas, which was exactly what I wanted. I told him I wanted to make a lettering enamel, and that it must have very good coverage. I asked him to add an additional 50% white pigment. He cautioned me that this would change the color, since white wasn't the only pigment in the paint. He also warned that it could affect the performance and drying time, since the proportion of binder to pigment would be thrown off. I said that this was a really tough paint, it should work, and I would take resposibility for it. I told him of how our usual oil based lettering enamel has been steadily deteriorating in quality due to envireonmental regulations. So he went ahead and mixed it as per my request. He started with a Peterbuilt White. The following describes what happened as I tried it for the first time. I'm grateful for his cooperation. I have only been to that store twice, but I have had a good experience each time.

|

|

|

|

| Home Page |

|

|

Restoring Coca Cola |

|

|

|

| Rat Rod truck door |

|

| Thanksgiving yard sign |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| The job this time is to put large white numbers on a black locomotive. I've done quite a few of these, at Knoxville Locomotive Works There are doors, hinges, and latches the length of the body. Even if you could get vinyl to adhere when you applied it, it would peel in time. Too many edges for weather to catch on, too much movement as doors are opened and closed. So paint is my choice. Up till this experiment, I used One Shot lettering enamel, as I have for years. What I do here is make a thin line around the outer edge of the letter, using an outliner brush. Then I use a 3 inch Sure-line brand mini roller to fill the middle. If you inspect the numbers closely, you can see where the two overlap. What is important to remember is that there is so much visual conflict created by the high contrast, that this textute is not very noticable. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

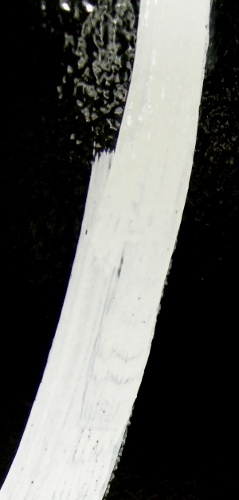

| The picture above right is a close up of the outline around the letter. If you look at the top of the picture, you'll see the good coverage I got on most of the work. In the middle of the picture is a thin spot. This picture used no flash, but it's still not accurate, the thin spot is a little worse than what shows here. This can certainly be attributed to brush technique. There were 3 of these thin spots on a 42 inch tall letter (about 1 meter?) Overall, I'm very pleased with the results. First, a warning, then the details of what I learned while using the product. |

|

|

Since this job was all brush and roller, no spray, I thought I could get by without using a respirator. Not so, the fumes are pretty strong, you'll need one. Maybe not as strong as multi-purpose screening ink, but still strong.

|

|

|

|

|

|

|

| The way I received this product , it was quite thin and runny. I decided to try it anyway. Maybe the binder in this product is just that way. This viscosity is actually very interesting. It's been awhile since I was able to use any thin liquid for lettering, save for ink in a caligraphy pen. I've been using latex paints (emulsion U.K.) a lot more lately, and I use them straight out of the can. Also, I still get decent results with One Shot lettering enamel, but it too requires that I don't thin the paint. There are two reasons I'm exploring the use of urethane/polyurethane: Some of the work I do with oil based paint gets a clear coat. This requires a careful application of the clear. Second, this locomotive is an example of work that will be used and handled right away. Oil based paint would remain soft longer, and be more susceptible to staining, when men open doors and latches. As far as viscosity goes, this is where it gets interesting. This product requires more attention in the way of not flinging drops everywhere. Also, a stroke that moves upward is better than the usuall downward. However it was surprising. Years ago, when I first was learning hand lettering, I was taught that you must regularly pallete the brush while using it. This kept fresh paint between the bristles, which flowed, instead of congealed. But the day I was using this product, it required little or no palleting. I guess the seriousness of the solvents kept it from congealing. Granted, I was in a shop, both the air and the surface were about 75 degrees F. A very pleasant and mild afternoon. Further testing will be done under more adverse conditions.

Back in the day, when paint was still leaded, and binder was stronger. a sign guy could thin his paint down and knock out a quicky sign. Some of those lasted for years. This product reminds me of those days. You can work off the tip of the brush, and still have good coverage. This means you can make script and casual stroke lettering easier. This could be very interesting. I have used acrylic automotive enamel before, and the results were always that it turned sticky fast, didn't have good coverage, and turned to melted Mozerella cheese if you used it with a roller. Not so here. Of course, further testing awaits. Till then I can only say that I am pleasantly surprised.

I mixed it up with about 10 percent hardener, and 2 or 3 percent rolling thinner. I think the product is intended to be used with 25% hardender. The rolling thinner is to slow drying time.

|

|

Contact Jim Donahue : Phone (865) 577-3365, or email

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|